Shilpa Sivakumaran: Pioneering Affordable High-Quality Music Gear with Sound Hammer

In-Conversation with Eshaan; Edited by Oshin

Gear has always been a crucial tool for musicians. We hone our skills through different instruments and tools to turn our craft into art and connect with people. Yet, finding high-quality equipment at affordable prices in India has always been a challenge.

That’s where Shilpa Sivakumaran comes in. As the founder of Sound Hammer in Hyderabad, she’s changing the game by offering musicians top-notch gear at prices we can all afford! I recently had the pleasure of chatting with Shilpa about her journey and how Sound Hammer is making music more accessible in India.

Her company is a breath of fresh air in the music gear space. Our conversation was a blast, and I found her interview truly enlightening.

E: I’m so glad we’re getting the chance to do this interview. Like most other guitarists, gear is an obsession of mine. However, while researching for this interview, I was hard-pressed to find out more about who you are, so let’s start there?

S: Yeah, the story is that I was always into manufacturing. Initially, I worked with pharmaceutical manufacturing and then with plastic molding. Most of my friends were musicians though, and we used to hang out all the time. One day, a friend was telling me how difficult and expensive it is to get a pedal board imported. After all the shipping and customs fees, the product ended up costing way more than what it was worth. I didn’t even know what a pedal board was, so he showed me a picture and I told him this was possible to make in India.

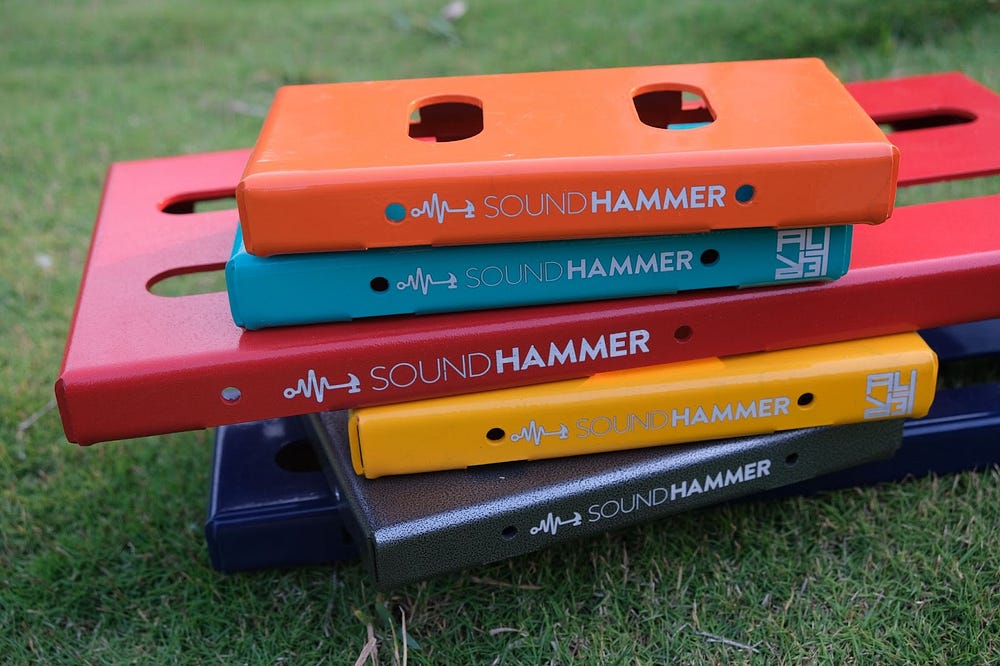

So, I made that first board for him, which in design was similar to the Pedaltrain board with welded aluminum rails. After this first board, more and more people started asking me to make boards for them. But I realized that this design could actually be improved. So, I took a month off and started Sound Hammer. The boards we make now are actually crafted from a single sheet of aluminum that is laser-cut and bent. This results in a sturdier and more lightweight design.

E: That’s amazing! As someone who has a Pedaltrain board, it is hard to imagine them being lighter. Speaking of design innovations, I saw your modular pedalboards. I had such a moment of ‘wow, why have I never seen this before?’

S: I had so many musicians reach out to me saying how they wanted a board but weren’t sure what size to get. People would say they wanted to buy two more pedals in three months and then a couple more by the end of the year. So, they would wait to buy a board until they had all their pedals — which is when I told them that they could get a smaller board and attach a second one once they had more pedals.

Design Innovations and Patents

E: Yeah, and even when I have a lot of pedals, sometimes for certain gigs, I just need two pedals, and for others, I need about 7. It’s quite a chore to dismantle and reassemble a board every time. What about the drum shields?

S: Yes, in fact, our modular pedal boards are patented. Most other boards that can be expanded only expand in one direction. Our pedal boards can be expanded in both the x and y axes. As for the drum shields, I saw that they were using regular hinges, this would create a large enough gap that allowed sound to bleed through, and they wouldn’t really function like drum shields. So, after doing some prototyping with PVC sheets and manually screwing them on, we landed on the final design. Our drum shields are made of two different types of plastic and are way more efficient. We also have a patent for the design of the shields.

Building the Sound Hammer Brand

E: So, what I am hearing is that even though all these products are made for musicians and manufactured in India, Sound Hammer is really a design company at its core. You are proving that all this equipment can be made in India and made better. What are some of the challenges you face as a business while interfacing with the music community?

S: The biggest challenge so far has been getting across the fact that a product made in India can be as good or even better than something imported. Before seeing our products, people often don’t believe that an Indian product could be better in quality than an American brand. It really is about getting the product in people’s hands because once they see and try our products, they fall in love with them and want to get one. So, over the last year, we’ve been working on building a brand and actually forming a community so that people know Sound Hammer. As a brand, we do not have that much value yet.

E: ‘Yet’ being the keyword. To me, your brand already feels different with all of its creative and handy designs.

S: For us, we do not want to just take a design, copy it, and then mass produce it. That would make our boards no different from what is coming out of China. We really want to look at what value we are adding to the music gear community.

Educating and Building a Community

E: I see on your Instagram account that you post a lot of educational content, demystify things like true bypass and myths about tube amps. Do you think educating people about these processes is a key step to overcoming some of your hurdles?

S: Yes definitely. It actually has two aspects. One is to get this information across to people. We’re doing this using Instagram and WhatsApp groups. We are also working on conducting workshops for musicians on setting up boards. The other aspect is building a stronger community. There are some people who are good at setting up the right boards, but there are a lot of up-and-coming musicians who do not have that experience. They are left going to places like Reddit — we want them to have a community that they can reach out to and learn from.

https://www.instagram.com/soundhammer.in/reel/C7YMvIFgKCU/

E: Any sneak peaks you can give us into future products?

S: Yes, we have a few coming soon. We already have soft bags for instruments, but we’re starting to make hybrid cases. They have a layer of polymer between them for added protection. The other product is a walk-up guitar stand. It’s a stand you can put on the stage and have your guitar in playing position, so if you have to switch guitars between songs, you can just walk up to it. That is another design we have patented.

E: Wow, I’ve never heard of that. That’s so cool. Just a guitar hanging on stage.

S: Most of our ideas come from talking to musicians and seeing what they want. There was something similar an American brand used to make but it’s now discontinued. Our design is very different though and involves a mount on a cymbal stand. So, there is a lot of freedom of movement and you can get the guitar in the exact place you want for playing.

E: I used to go to the Srishti School of Art and Design, so I am sure there are a lot of scrapped iterations before you get the one right design?

S: Oh, we have a graveyard of bad designs.

E: Speaking of community, gear is such a bonding factor. The moment you see someone play the same gear, you feel a certain kinship to them. Any plans on working with younger musicians who are just starting out?

S: Yes, the workshops we were talking about earlier, we want to take them to music schools and show people how they can build their first board or improve on what they have.

E: In your own vision of Sound Hammer, do you see it as a niche boutique company or a more mainstream name? Not that I personally know what boutique even means anymore but I guess both have their pros and cons.

S: Three years ago, when I was the only person running Sound Hammer I would have been very happy calling it a boutique company. But now, we have a team of people working with us and still have niche products like custom pedal boards and the double-leveled boards that we make, and will continue to make. That’s where our passion lies. For the rest of the company, I would rather it be a more common name in the industry because it makes getting a good quality product for anyone more accessible instead of having to go and import a board.

E: Any plans to move beyond online and into stores?

S: We definitely want to leave samples in stores. Like I said earlier, once people see the boards, they trust the quality. Our biggest challenge really is changing the perception in people’s minds about the quality of an Indian product. Our boards are made with aluminum, corrosion resistant, and are powder-coated, not painted. These are small things that add up.

E: It takes a lot of courage to quit a job you have and join a relatively niche field. You now have a team working with you, do you have any advice or encouragement you would like to offer for people on the brink of making such a decision?

S: Well yes, you have to take risks, but it has to be a calculated risk. For the first two years, I had no employees. I did everything myself, from manufacturing to shipping to customer relations. It was completely self-funded, and we were working out of our homes. The company grew slowly and organically. We started hiring only when I realized that if I do this alone, I would be doing the same thing over and over again, and there would be no one to look at the big picture. If we had to move beyond day-to-day operations, I needed a team. It is still a small team but it has grown organically and in a step-by-step way.

Through Sound Hammer, Shilpa’s innovative journey proves that high-quality music equipment can be made locally, overcoming import challenges and shifting perceptions about Indian-made products. With a focus on design, education, and community building, Sound Hammer is undeniably set to make a significant impact in the music industry.